Transoceanic Fiber Optics: The Cable That Runs the Tech World

Posted by Scott Mortenson on Mar 16, 2023

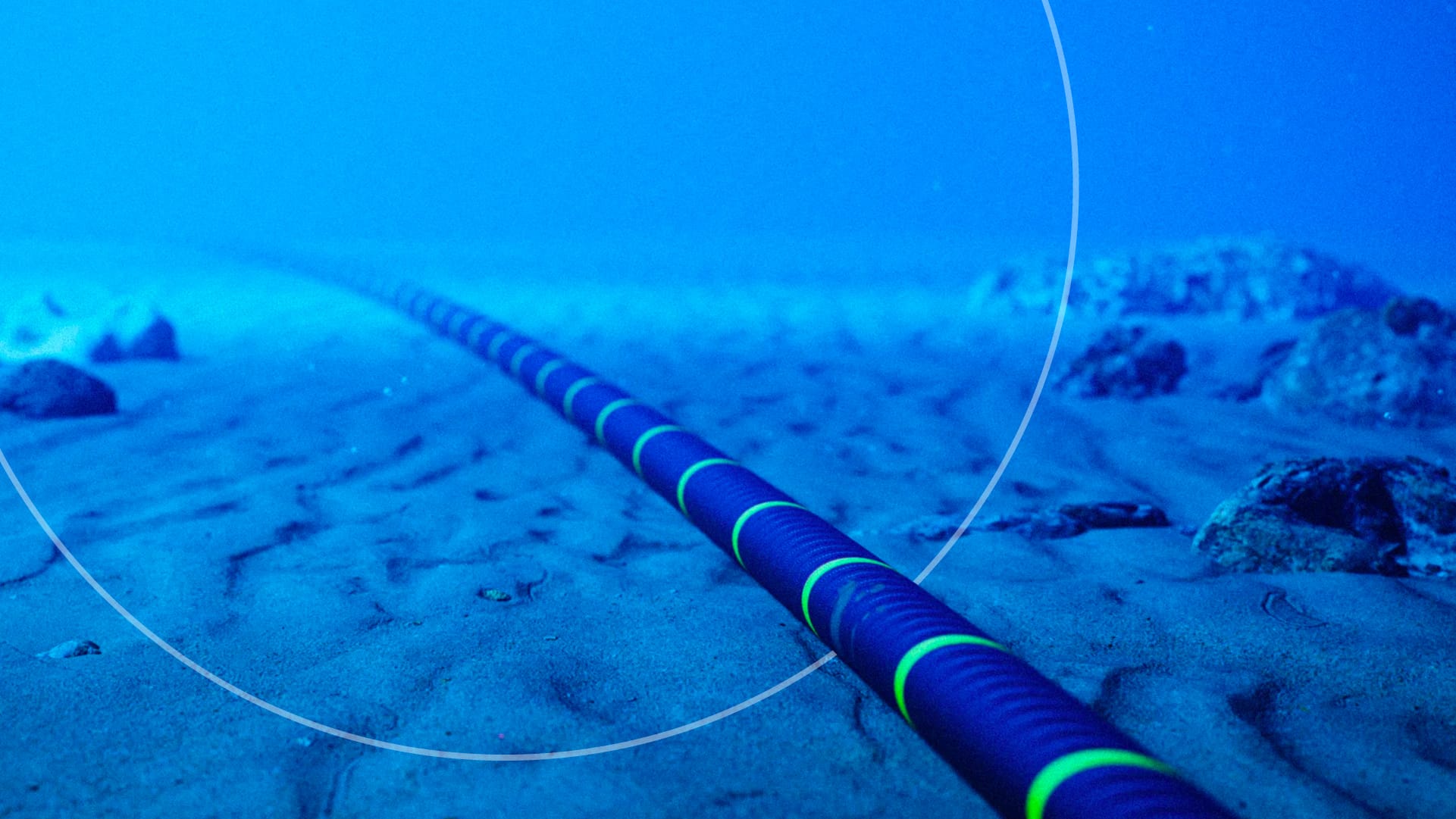

A few years ago, an underwater cable broke, plunging a nation into Internet darkness. While some may say not having Facebook for a few hours is a positive thing, this was more than that, called “an absolute disaster . . . a national crisis.” It cut off not just social media, but email, cell phone service, financial transactions, business, and government communications.

It's still not clear what caused the breakage, but it was fixed about two weeks later.

And then, in 2022, it happened again. Only this time, it was worse.

You may recall seeing news on the Tonga volcano eruption and tsunami that left at least 6 dead, 19 injured, and others reported missing, with $90.4 million in damages. Besides bearing a devastating natural disaster, the people in Tonga lost their main connection to the outside world.

We can certainly understand why a volcanic eruption hundreds of times more powerful than the atomic bomb would take out a transpacific fiber optic cable, but it also underscores the fragility of our digital lives.

A Brief History

In a way, the whole idea of laying a cable on the bottom of the ocean floor almost sounds like science fiction. How does a cable thousands of miles long even get made? How do they get it on the boat? How do they lay it on the ocean floor?

Cable breakages on land are bad enough, with everything from construction equipment, fires, even vandalism disrupting the fiber optics. But land “interruptions” are relatively easy to fix. How do they get repaired 25,000 feet (about 7.62 kilometers) underwater?

Communication cables laid on the ocean floor were not created when the Internet came along. The first “submarine cable” was dropped into the water in 1858, but only lasted about three weeks. It was attempted again in 1866, and worked, sending telegraph signals across the Atlantic. Telephone communications (i.e., AT&T) used underwater cables beginning in 1956 and the Internet started utilizing them in 1988.

Today, some estimates say there are 550,000 miles (about 885,000 kilometers) of transoceanic fiber optic cables, while others claim 750,000. That’s like stringing a line from the moon and back twice. Whatever the actual number, it is a lot, which means “The Cloud” is not really in the sky, but 5 miles underwater.

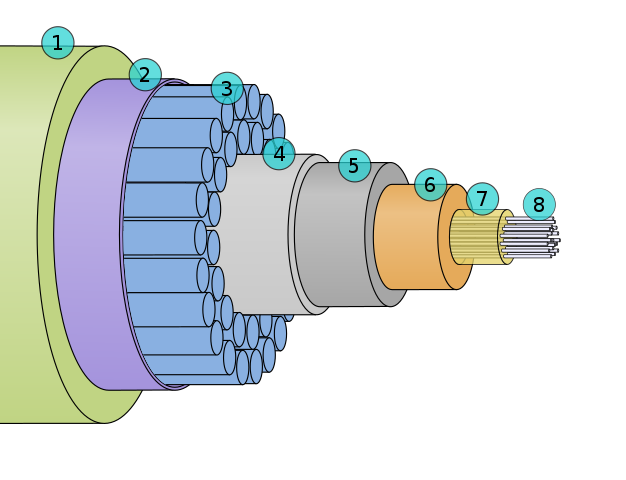

The cable itself is just a little bit more complex than its land-locked cousin. A “standard” fiber optic cable has a core, a cladding layer, and is usually coated with acrylate polymer or polyamide. There could be more layers of protection, depending on the application. Inside all of that is the optical fiber which carries the light. A submarine cable resting on the bottom of the ocean has more layers to protect it than a land-based one, like a scuba diver wears more than just a swimming suit.

A cross section of the shore-end of a modern submarine communications cable.

1) Polyethylene, 2) Mylar tape, 3) stranded steel wires, 4) aluminum water barrier, 5) polycarbonate, 6) copper or aluminum tube, 7) petroleum jelly, 8) optical fibers

Despite all this protection, an underwater cable can be damaged not just by volcanoes and tsunamis, but earthquakes, storm currents, ship anchors, and fishing trawlers. Even sharks looking for a snack.

Politics get involved as well, with both transoceanic cables and pipelines being sabotaged or blown up over governmental agendas and spats.

How The Cables Are Made

As for the manufacturing process of undersea cables . . . yes, it is a big process. The cables are fed into a high-speed mill the size of a jet engine, put in a copper casing that may have plastic, steel or aluminum and even tar added to protect it from the elements.

You may think the end-product is fat and big, but it’s about as big as a larger-size garden hose. And the cable is designed to last 25 years if not subjected to volcanoes, earthquakes, or fishing trawlers.

The planning of where the cable is laid in the ocean takes at least a year so they can arrange its course miles underwater, where the seabed has been charted but a little unpredictable. After all, there are both trenches and mountains down there.

Implementing The Fiber Optic Cable

Alcatel Submarine Networks (a part of Nokia) has more than 700,000 kilometers (435,000 miles) of optical submarine systems deployed worldwide (enough to circumnavigate the globe 16 times). One of the ships used to deploy the cable is about 450 feet long and can have as many as 80 crew members, with teams working in two 12-hour shifts. Although they have plenty of food for their long journey (two months or more), alcohol is not allowed. That’s for the better since the seas can be rough, sometimes so bad the captain may order operations to stop, cut the cable and find safe waters. Before cutting the cable, they tie a buoy to it so they can find it when they return.

Of course, the ship does not carry enough cable to span the whole ocean, so it is done in segments. The ship can carry up to 4,000 miles (about 6437.38 km) and it can take a month for the gigantic tanks (where the cable is stored) to be fully loaded.

A special subsea plow is used to trough and bury submarine cables along the seabed closer to shorelines where things like anchoring and fishing are most prevalent and could damage submarine cables.

Out at sea, the cable is unspooled into the water, attached to several buoys temporarily so it doesn’t sink to the bottom too soon. Once out far enough, the buoys are removed and the cable sinks to the ocean floor. This is repeated over and over.

Those of you who are thinking “Wait a minute! The light in fiber optics can only go so far before it loses strength — how can a cable traveling thousands and thousands of miles keep the signal alive?”

Repeaters placed every 60-70 kilometers — about 40 miles.

The Technology of Submarine Cable

Power to the repeater is fed from power feeding equipment, which is located in Submarine Cable Station. In traditional submarine cables, every fiber pair will have their own repeaters, and four fiber pairs will have a repeater with a four-amplifier chassis. One amplifier chassis has dual laser 980nm pump units. This is called 2x2 Pump redundancy, the type of redundancy scheme used in the past.

Now they use 4x2 redundancies, improving reliability by using additional 2 pump lasers compared to the 2x2 pump redundancies. Two EDFA’s share the power from four pump lasers, which can tolerate three-pump laser failure at most in each fiber pair.

The submarine cables use DWDM (Dense Wavelength Division Multiplexing) so the data capacity is maximized at hundreds of Gbps (gigabits per second). The cables also employ optical amplifiers (a.k.a. repeaters) that boost the signals across each cable section.

So, yes, laying a cable from, say, Oregon to Japan is quite complicated and time-consuming to say the least.

From Land to Sea to Land

Once the cable (or more accurately, series of cables) reaches its land-based destination, it is connected to submarine line terminal (SLTE) and power feed equipment (PFE) installed at a cable landing station. The PFE can be installed at a cable landing station, while at another inland location — such as a data center or central office — the SLTE is set in place.

There is, like everything in the tech world, much more to the technology, but that is a basic look at how your laptop gets connected to a webpage in Japan or Spain.