The Key is in the Quality

Posted by Tim Yanda on Dec 18, 2023

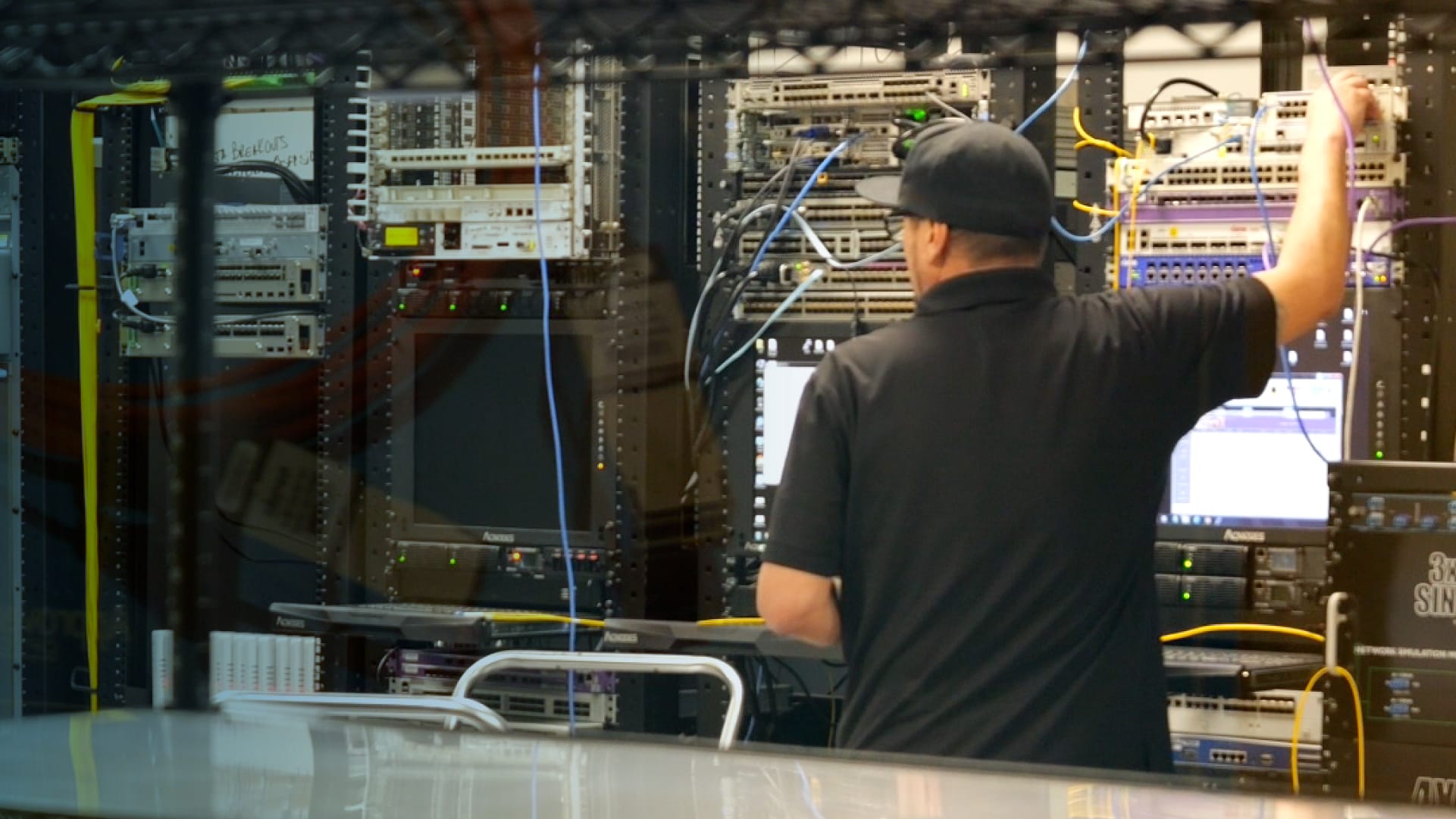

A highly reliable network is a basic requirement in a high network demand with outstanding bandwidth to support the growing connectivity needs. Approved Networks has a robust quality control system to deliver a top-in-class performance. The two locations in Ohio and California follow stringent standards to ensure transceivers, passives, and cables meet or exceed specifications.

All parts go through a strict qualification process that the Engineering team closely manages. Once parts are approved for general acceptance (GA), they have gone through optical power, DOM/DDM testing, EEPROM standardization, and compatibility coding as required. All testing must pass before a part is moved into GA classification. This testing is completed in our AN's state-of-the-art quality labs. Our equipment allows us to optically measure power levels, error tolerance, stress test, traffic test, and environmentally test for popular protocols (Ethernet, Fibre Channel, InfiniBand, CPRI, SONET, etc.)

Once a part is considered GA, it is tested inbound to the coding labs. When the part is built for specific compatibility, it is tested in the switch being coded for and prepared for shipment to the customer. A tracking system is in place where a part is identified via its serial number and can be traced through the entire testing, coding, and shipping cycle. Tracking is key to ensure it is clear how the part is performed and when the customer receives it. If there are questions, we can follow the entire process to assist in any troubleshooting.

AN has adopted a Gold Standard process that requires EEPROMs to be standardized and uploaded to the manufacturing system. The QC team is responsible for validating EEPROM coding and following the strict standards. By having coding consistency, the customer will receive parts that perform the same all the time. You ask why this is important. Monitoring systems and processes are in place at the customer site to manage the network for the highest reliability. The monitoring systems will not know where to look for the data if inconstancy occurs.

Regarding passive mux/demux systems, ensuring channel configurations are correct, and insertion loss meets specification is critical. Passive systems have extremely high-reliability requirements; the design, manufacturing, installation, and testing are critical steps to maintain the highest reliability. The testing that AN completes is channel-specific and meets all design standards. The state-of-the-art light sources, optical spectrum analyzer, and traffic generators all ensure the parts meet the requirements.

AN strives to have zero defects; our parts typically exceed the five nines of reliability. The meager defect rate gives the network operator high confidence in AN products. Our parts run the internet worldwide. As you read this article, there is a very strong likelihood that an AN transceiver power is a part of the circuits that are delivering the news to you.